Death of local apparel manufacturing is nigh

View(s):The problem with being emotional and political about an argument is that one misses some important cues that in hindsight can cause disruptive change. The current discussion on the hard hit local manufacturing sector is a case in point. In their eagernss to find an excuse for their falling fortunes, management, especially in the apparel sector has the ultimate fall-guy: losing GSP Plus concessions. If only life was that simple. Tax concessions or preferential access arrangements are always fleeting. Anyone who makes capital allocation decision on short term trade preference deals is at best taking on a leveraged bet that the scenario remains unchanged and shows complete ignorance of the political economy.

What’s about to bite our manufacturing industry will have a profound impact on the broader economy and society. This will be the domestic episode in a global drama. The drama is called 3D Printing. The actors include developed market central bankers, accounting standards in how companies can treat their debt vs. equity in the capital structure, and most importantly disruptive technological innovation. Advances in robotics and material usage will be the leading cause of manufacturing job losses in the apparel industry over the next three to five years.

3D printing or additive manufacturing as it has been colloquially known takes 3D models and prints different layers of material to deliver a physical end product. While additive manufacturing has been part of overall manufacturing process since the 1970s, 3D printing has enabled comprehensive delivery of a product from design to end-user, by-passing all the layers in between. This will open up two distinct advantages for retailers; mass customise products and move manufacturing closer to their markets in order to deliver faster.

What’s enabled the massive advance in technology over the last five years have been record low interest rates in the developed world and preference rules for debt over equity in the capital structure. This has enticed corporates to favour large capital expenditure (which is in turn financed through cheap debt, which can also be written down for tax purposes) aimed at efficiency gains (a cute way of saying automation). Productivity gains across major economies have led to a rise in unemployment.The large capital spend has thus far been limited to bulk good and technology manufacturers. In January the US economy added just 4,000 manufacturing jobs, and the net increase since July is zero. Yet last month, manufacturing activity rose by its fastest rate since April, according to the Institute for Supply Management. The difference boils down to robots. Manufacturing employment is shrinking around the world. Among other countries, China is moving even faster towards industrial robotics, an area in which German and Japanese manufacturers dominate. Last year Foxconn, the Shenzhen-based assembler for Apple, Nokia and others, said it was buying one million robots in the next three years to substitute for workers performing repetitive manual tasks. At the other end of the spectrum, a restaurant in Harbin, northern China, last year became the first to be entirely waited on by robots. Last month, China opened the world’s first museum of 3D printing, according the Financial Times of London.

What’s enabled the massive advance in technology over the last five years have been record low interest rates in the developed world and preference rules for debt over equity in the capital structure. This has enticed corporates to favour large capital expenditure (which is in turn financed through cheap debt, which can also be written down for tax purposes) aimed at efficiency gains (a cute way of saying automation). Productivity gains across major economies have led to a rise in unemployment.The large capital spend has thus far been limited to bulk good and technology manufacturers. In January the US economy added just 4,000 manufacturing jobs, and the net increase since July is zero. Yet last month, manufacturing activity rose by its fastest rate since April, according to the Institute for Supply Management. The difference boils down to robots. Manufacturing employment is shrinking around the world. Among other countries, China is moving even faster towards industrial robotics, an area in which German and Japanese manufacturers dominate. Last year Foxconn, the Shenzhen-based assembler for Apple, Nokia and others, said it was buying one million robots in the next three years to substitute for workers performing repetitive manual tasks. At the other end of the spectrum, a restaurant in Harbin, northern China, last year became the first to be entirely waited on by robots. Last month, China opened the world’s first museum of 3D printing, according the Financial Times of London.

Automation in technology manufacturing has driven costs down by 35 per cent in some processes and up to 65 per cent in others. This is way above any tax concessions bestowed by a treaty. The little that is left of local manufacturing has survived thanks to higher value added end products (mostly restricted to lingerie) and more importantly the slow creep of technology into the apparel sector in general. All that changed in 2010, when 3D printing debuted on the fashion runway at the Amsterdam Fashion Week. More disruptive to the local trade however comes from a brand new American start-up called Continuum Fashion. They have created the first 100 per cent 3D printed finished clothing item. Unfortunately for Sri Lanka’s apparel manufacturers that item happens to be a female bikini, called the N12 bikini. N12 stands for Nylon 12, a flexible, nylon-based plastic used in the 3D printing process. The price for the N12 bikini currently is higher than the median for say Victoria’s Secret, Sri Lanka’s top purchaser. That difference would collapse over the next two years.

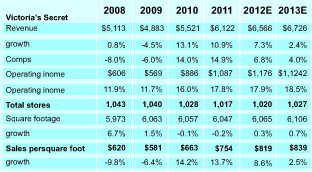

From an unemployment and national budget perspective these changes will cause major disruptions. Most local analysts and manufacturers were sanguine when I met them last month, saying that Limited Brands Inc. (the holding company for Victoria’s Secret) is in good shape and while margins are under severe strain, the status quo will remain. Dream on I said to them then, and I say to them now. This isn’t an exercise of how well Limited Brands will do as a company. In fact speaking to them and closely following their fortunes, it appears they will continue their dominance as a brand as they diversify their retail presence globally. Note the median expected growth over the next two years as reported by analysts who cover the stock provided in the table.

The problem here is for the national budget and by extension all citizens, not only those in the apparel sector. As apparel manufacturing disappears due to disruptive technology, Sri Lanka is getting caught in a trap with no way out. There hasn’t been forward planning on moving to neither other higher value manufacturing nor a strategy to promote 3D printing technology locally. As highlighted in this column some weeks back softer cultural issues and political thugocracy is keeping creative destruction at bay.

In an adverse scenario of apparel manufacturing losing 75 per cent of its value over a 18 month period, there will be a general collapse in demand and consumption taxes fall with rising unemployment. It’s important to remember that most manufacturers have signed wonderful contracts that prevent them from paying direct taxes to the government, and most of the transmission will be to external reserves and consumption.

Economic adjustment after the immediate collapse of the sector will be difficult to navigate as there appears to be no strategic thinking by either the Treasury or Central Bank on crisis economics. Most likely outcome includes a bout of hyperinflation as the rupee collapses. The best case scenario paints a sorry picture. The collapse will be sudden and severe; the rebuild painfully slow and gradual. It’s anyone’s guess as to the security and social ramifications of a collapse scenario. An ageing demography makes a violent revolution highly unlikely.

Some protection may come our way as a result of this disruption being a global problem as alluded to earlier. It is very likely that Governments in developed economies will have to grapple the same problem over the next two years, and thus create some rebalancing to slow down the negative impact of advances in technology.

One thing we hope Governments around the world and in Sri Lanka will learn comes from a meeting between Henry Ford and Walter Reuther, a union leader at his Ford factory. Pointing at his new robots, Mr Ford says, “How will you get union dues from them?” Mr Reuther replied: “How will you get them to buy your cars?” Eighty odd years on, that remains the hardest question to answer for most governments around the world. Unfortunately, it’s far more difficult for their local counterparts.

(Kajanga is the founder of Delaware based Centre for Investor Behaviour and currently resides in Sydney, Australia. You can write to him at kajangak@gmail.com).

Follow @timesonlinelk

comments powered by Disqus