News

DPL’s CSR dips as the gloves come off its operations

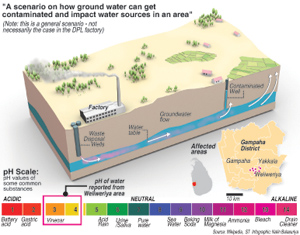

The agitation for clean water in Rathupaswala has ended with deaths, injuries and damage to property. A joint investigation is being conducted by related government agencies to ascertain who is at fault for the water pollution. However, environmentalist Sajeewa Chamikara of Environmental Conservation Trust points his finger directly at the factory, for the improper release of industrial waste, as a cause for this catastrophe.

He alleged that the factory has been releasing waste water into the environment without being properly treated, which rendered the area’s ground water acidic. He also blames Central Environment Authority (CEA) and Board of Investment (BOI) for not properly monitoring the factory’s process.

The problem in Rathupaswala emerged when villagers requested the Water Supply and Drainage Board (WSDB) to test the water, after several of them had fallen ill, as they felt something was wrong with the quality of water. Results revealed that the pH level of the water was lower than 7 (normal), which means it is acidic. Pure water has a pH very close to 7; but the water in Rathupaswala had a PH level around 4, as alleged by the villagers.

Villagers then lodged a formal complaint at the regional office of the CEA in Gampaha. CEA Director General, Dr Saranga Alahapperuma talking to the Sunday Times confirms that the agency’s Gampaha regional office has received a formal complaint on July 16, and next day they sent a team to investigate. Later, a BOI investigation was started. The DG said that an investigation of this nature takes at least a fortnight for the results. Unfortunately, events unfolded on August 2 taking 3 lives. Now a joint investigation is being conducted by the CEA, the BOI, the WSDB, the Geological Survey and Mines Bureau (GSMB) and experts from several universities. He said the results would be released by next week.

The factory at the center of the controversy is Dipped Products Ltd (DPL) owned by the Hayleys Group. which was set up in 1994 in Nedungamuwa, Weliweriya, as a BOI project. The plant manufactures Latex Gloves by processing natural rubber, which involves many chemicals. As a result, the processes generate many harmful industrial waste that require treatment to dilute their harmful nature, before release into the environment. There is a provision that the BOI can issue Environmental Protection Licences (EPL) under the National Environment Act, after obtaining concurrence from the CEA, and the factory has been offered initial EPL.

CEA DG admitted that approval for the EPL’s renewal, which is an annual requirement, is usually granted on reports submitted by the company seeking same, unless there is a complaint, when the CEA then conducts investigations. He also admitted the importance of having independent analyses from time to time, which mechanism the agency is looking at in the future.

Meanwhile, it is also alleged that the sludge – or residual materials left from industrial wastewater – has been dumped in the area sans any precautions. When the Sunday Times queried about this, from DPL Managing Director Dr Mahesha Ranasoma, he said that, prior to January 2012, the factory was disposing solid waste at landfills known to the Pradeshiya Sabha (PS). From January 2012, the company entered into an agreement with GeoCycle (Holcim Lanka Ltd.) whereby, GeoCycle disposes the solid waste, with the exception of wood ash, unutilised wood chips and waste cotton, which are disposed at PS approved sites.

Denying all the other allegations, Dr Ranasoma said the factory complies with CEA and BOI standards for releasing rubber industry effluents to the surface water, and operates under the renewed EPL. He pointed out that for the processing of rubber, Alkaline chemicals are mainly used, not the acids. So the pH value always remains higher than 7, should pollution occur. He added that, DPL does not use any acid for the manufacture of rubber gloves. However, they use a commercially purchased acidic material (10%-30% mixture of Nitric and Sulphuric acid) for mould washing. This acid is always re-used by topping up with fresh material. If we do need to dispose it, we treat it the same way as the mould washings described above.

Dr Ranasoma also said that their effluent water quality is regularly tested by the National Building and Research Organization (NBRO) every three months. He said they are disposing the treated effluent according to EPL standards, to designated soakage areas which is their coconut land. Their treatment plant is designed to cater to up to five plants, according to Dr Ranasoma.

It is claimed that Nedungamuwa, Weliweriya, is an area where shallow water could have a natural pH less than 6.5. Chemistry professor O.A. Illeperuma says there is a possibility of the soil being naturally acidic in these areas due to the presence of laterite, which is an iron rich mineral.

The red soil resulting from the disintegration of these lateritic rocks is fairly widespread in the Western province including the Gampaha district and also around Nugegoda and Maharagama. Hence, the village derives its name “Rathupaswala” from the presence of the red soil, opines Prof Illeperuma. Such soils have high concentrations of iron- in the ferric form – by bonding with water (hydrolysis), which renders it acidic.

Prof Illeperuma too says that he cannot understand how this type of pollution has arisen all of a sudden, if this theory is true. However, in order to verify this, it is necessary to do a comprehensive water analysis programme of the affected and surrounding areas, points out Prof Illeperuma. So, there seems to be more questions than answers at Weliweriya as to who the real polluter is. But whoever it is, the fact of the matter is quality of the water has deteriorated, to the detriment of the welfare and wellbeing of the people of Rathupaswala.

Industrial water pollution a regulatory failure: Environmentalists

Hemantha Withanage of the Centre for Environmental Justice (CEJ) reveals there are hundreds of such cases of pollution linked to industries in Sri Lanka, and highlights the need for preventive actions through regular independent monitoring.

Whoever is responsible for the water pollution in Rathupaswala, the incident is also a clear indication that regulatory measures are not being properly implemented, making it a dire need for its strengthening to prevent future pollution case, points out Mr Withanage. He said the issue of environmental licences also needs to be evaluated, and the water sources in the vicinity of factories, notwithstanding their effluents, regularly monitored.

Mr Hemantha insists that Water Quality undergo comprehensive testing for an accurate extent of pollution. For example, Tolerance Limits for Industrial Wastewater in Sri Lanka lists 22 parameters including harmful chemicals such as arsenic, and pH level is only one of them.

He says these tests have to be conducted independently, which, if the CEA had done, this problem would not have gone this far. He also was displeased with the process of issuing EPLs, pointing out that the process is not properly governed due to corruption.

Environmental Organisations too have a role to play, some concerned citizens points out, taking India as an example. Some of the green NGOs in India, such as Centre for Science and Environment (CSE) conduct their own investigations in air and water pollutions. These kinds of independent investigations should be done in Sri Lanka too.

However, these tests are costly, and to check all the parameters, the test costs Rs 39,000, added Mr Hemantha.

Follow @timesonlinelk

comments powered by Disqus