Benchmark yourself and step towards improving water efficiency

The pressure is on . climate change has put water resources in danger in terms of both quantity and quality. Meanwhile water quality is degrading as a result of poor water management practices adopted in developing countries.

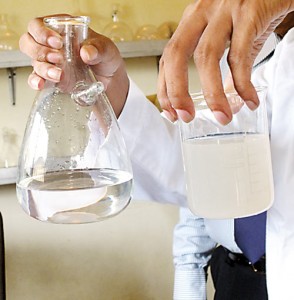

File picture of purified water extracted from waste water

Agricultural, industrial and municipal sectors of Sri Lanka consume 87.3 per cent, 6.4 per cent and 6.2 per cent of fresh water, respectively. Although industry accounts for only 6.4 per cent of total Sri Lankan fresh water use, improving water practices in industry is a key focus for government.

Increasingly, having understood its importance, industries report, monitorand most importantly continuously improve their water efficiency.

Water management in industry has two major components; reduce overall water usage and trade waste discharge while improving water discharge quality.

Trade waste is any wastewater discharged from commercial, industrial, laboratory or trade activities. It specifically excludes wastewater from private residences. Trade waste management is an important issue for many industrial users and can often contribute significantly to operating costs.

Any savings achieved in reducing water usage should, therefore, also be measured against the reduction in trade waste volumes and costs.

Industrialists should benchmark their water consumption before setting targets in reducing water usage. A benchmark is a number against which you can measure your own water use. It is generally either an average of a large number of users with a similar water use profile or a best-in-class number for a specific type of water use or industry (the lowest water use per 1 kg of product per year among all similar sized and type of industries for example). If they exist, you can also utilise best practices that have established a water use numeric for your sector.

A benchmark gives you a target. For example, industries are estimated to use 9 m3 of water/employee/annum in domestic use as reported by the European Commission.

The industrialists can compare this value with their domestic water consumption and identify opportunities in water efficiency improvements.

The first and foremost requirement in establishing benchmarks is to know your total water consumption and the activity water consumption. In most of the Sri Lankan companies where water is pipe borne water from the main supply, the water bill is paid but nobody understands its usage properly.

The companies who obtain ground water from the wells do not know even the total consumption. These companies can use simple tools and techniques to quantify their water usage.

Water auditing is a very useful tool in determining exactly where water is being used and what purposes and times (industrial process, landscape, toilets, dishwashing, laundry, etc) and how much could potentially be saved in each category. A water audit will look at not only the quantity but also quality of water. For example why should a company use high quality water for flushing of toilets, gardening or vehicle washing? Are there opportunities to practice 3R (Reduce, Reuse and Recycle) in water usage. A detailed water audit can even critically look at internal operations and eliminate excessive water consumption in some operations. A simple water audit can be a do-it-yourself project. For a more complex or in-depth evaluation of water use it’s best to have a professional audit done.

Water saving options can vary greatly depending on the operations of an enterprise, from regularly maintaining the cooling tower to reduce blowdown, to increasing the blowdown threshold of the cooling tower, changing spray nozzles on equipment, and improving work practices and attitudes to water in the site.

Looking closely at the production process may also enhance water efficiency.

Industrialists may be able to make changes to how production is scheduled, for example, batch wise products to reduce cleaning in between runs.

For example, the Hokandara Press Complex of Wijeya Newspapers Ltd could save 20 per cent of water annually from total consumption while 52 per cent from total water consumption is recycled and reused. Water saving was achieved through several water management initiatives including replacement of the urinal system, reuse of condensed water from the AC system, installation of waste water treatment plant and changing the shower system. They have won recently the National Green Award granted by the Central Environmental Authority (CEA), The Global Green Award by “OMAC” Other ways Management Association Club and National Cleaner Production Awards (Silver Award) by National Cleaner Production Centre Sri Lanka for improved environmental performances including water.

In the local context, most of the industries are having a great potential in water efficiency improvements. The National Cleaner Production Centre of Sri Lanka (NCPCSL), established under Ministry of Industries and Commerce in 2002 has been working with local industries to improve resource (water, energy and material) efficiency. It has served more than 200 industries in optimising efficiency while reducing cost. The NCPCSL will assist your industry to benchmark industrial water consumption and conserve water through technical and behavioural changes with good housekeeping practices.

Let’s join with the NCPCSL and benchmark your industry and improve water efficiency.

(The writer can be contacted at contactus@ncpcsrilanka.org or

nisansala@ncpcsrilanka.org)