Sri Lankan planters explain how production cost of tea is determined

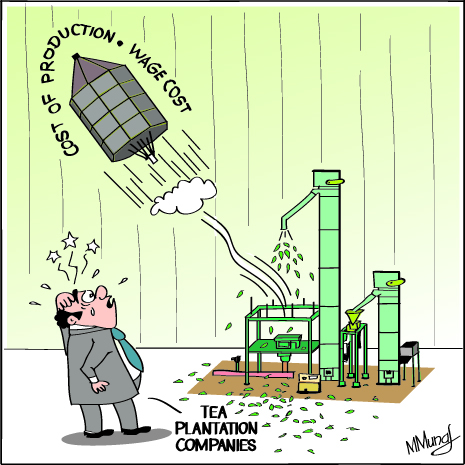

View(s):To facilitate open discussion on the critical issue of cost of production (CoP) of tea and affordability of estate sector wages, the Planters’ Association of Ceylon has shared the relevant calculations in a media statement.

The association, which represents 22 Regional Plantation Companies (RPCs) collectively employing nearly 200,000 workers, said that together with the Employees’ Provident Fund (EPF) and Employees’ Trust Fund (ETF) obligations, the daily cost borne by a plantation company in employing an estate worker is approximately Rs. 700 (excluding other commitments such as gratuity, holiday pay and attendance bonuses etc).

The daily plucking average of an estate worker in the country is around 18 kg (based on annual figures) which is usually the upper limit when climatic conditions are most conducive. The actual average is often lower; particularly in the case of male pluckers. During the dry season and amidst extremely wet weather, the daily plucking average often drops to 14 kg to 12 kg. The 18 kg of tea leaves plucked converts to 3.87 kg of made black tea, also referred to as Plucking Labour Output (PLO).

With regard to gender division of plantation sector workers, around 52 per cent are female and nearly all women are engaged in harvesting/plucking, while 48 per cent of the workers are male. Therefore in total only around 55 per cent of workers employed by the RPCs are pluckers as workers are required for other agricultural activities such as weeding, fertilizing, upkeep of plants and other agronomic activities – without which plucking cannot be carried out – and factory work. Thus, the actual output per worker (including pluckers as well as other agricultural and factory workers employed) is only 2.12 kg of made tea [(3.87/100)x55]. This is referred to as Revenue Labour Output (RLO), the PA release said.

The total labour component of the cost of production of tea can therefore be arrived at by dividing the Rs. 700 (borne by a plantation company per plucker per working day) by the Revenue Labour output, which amounts to Rs.330 (Rs. 700/2.12).

However, the labour cost is only approximately 67 – 70 per cent of the cost of production of 1kg of tea as additional expenses are incurred on other inputs including chemicals, material, fertiliser, fuel and on staff providing support services relating to health, welfare and childcare etc. in the estates – which primarily benefit the pluckers themselves. Thus the total cost of production amounts to Rs. 471 [(Rs. 330/70)x100].

At the Colombo Tea Auction however, the monthly auction average for April 2015 was only Rs. 408, thus representing a loss of Rs. 63 pereach kg of tea sold by RPCs.

These calculations indicate that to breakeven (assuming no change in other variables), the daily total cost per plucker incurred by a company at the price which prevailed in April 2015 at the Colombo Tea Auction, should be approximately Rs. 580, despite the figure actually being in the excess of Rs. 700. Alternatively, at the present level of output, for companies to break even the average at the Colombo Tea Auction should be in the region of Rs. 470.

Not taking into account biological revaluation of assets – which only represent accounting/book profits and arise as a result of plantation companies having to comply with International Financial Reporting Standards (IFRS) – 19 RPCs represented by the PA collectively made a loss of Rs. 2,850 million on tea and rubber in 2014.