Local brushware and filament maker, Beira Group eyes Southeast Asia

Sri Lanka’s leading brushware and filament manufacturer and exporter, Beira Parawood Products (Pvt) Ltd (BPPL) is looking at Southeast Asia as its next big market to tap. The company’s CEO Anush Amarasinghe told the Business Times that the company was looking at the above region as the next level to take its products. He made the comment during a media tour of the group’s factories at Ingiriya and Horana last week.

Cutting the wood. Pix By Ranjith Perera

Mr. Amarasinghe said, “The higher the disposable income and the per capita income, the greater the chance people would pay a higher price for good quality products. We will announce our plans for Southeast Asia in the next three to four months. Some of the Southeast Asian markets are interested in buying our products because they are reaching a stage where domestic health is becoming expensive. The moment that happens, they buy good quality products paying more money. This is where we are now looking forward towards growth.”

Reflecting on why West Asia is not their choice of a market, he noted that, “West Asia is a tough market. Though there is a lot of construction happening in there, for most of the construction work they hire people from this part of the world, from India and Bangladesh. The moment they do that they don’t spend on good quality products but buy cheap products.”

CEO Anush Amarasinghe

Mr. Amarasinghe also revealed that Sri Lanka is getting to the point where when the per capita income goes up to around US$ 5,000 people will start to spend money on good quality products. “The company will be selling the products soon at Arpico Super Centre, Cargills Food City and we are also in discussions with Keells Super because the type of shoppers they have would pay more for good quality products.”

The company started to manufacture the products in 1986 as an export oriented company. “One of the things that we have learnt is that the moment you start to manufacture any product with a lower quality it’s difficult to go up. It is always better to start from the top end and work your way down which is much more sustainable than going up,” stressed Mr. Amarasinghe.

Some 30 per cent of the products manufactured at BPPL go into the construction industry while 30-35 per cent is used by the cleaning industry.

Almost all products are sustainable and environmentally-friendly. Every time a tree is cut to manufacture brushes a new tree is planted and empty plastic bottles are recycled to make plastic filaments of the brushes. Nearly 99 per cent of the products manufactured at BPPL are exported. The company has five factories in four locations with 650 employees. There is also a large share in the Australian market while the company exports to some 18 countries. Some 70 per cent of products are exported to the US while 13 per cent goes to Australia and New Zealand. Europe and India are growing markets.

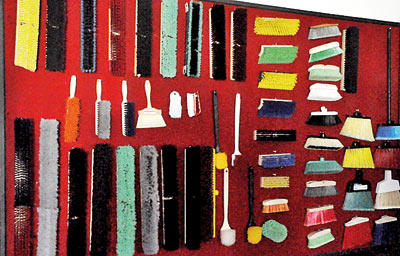

Display