Sunday Times 2

Re-energising NVQ: A fillip to national economy’s local skilled partners

Sri Lankan skill is second to none in the world. While the irrigation marvels from the days of the ancient royals still astonish the modern engineer and the Sigiri feat continues to enthral the whole world, with only the inherited skilled gene in them, our masons, cooks, welders, carpenters, tailors, cinnamon peelers, tea pluckers and rubber tappers become skilled partners in the national economy, mostly with no paper qualification endorsing their talents.

Project in progress at Polytex Garments

In a bid to give recognition to those who opt out of the conventional education system of the country and pursue technical and vocational paths, the Tertiary and Vocational Education Commission (TVEC), in 2005 took measures to introduce a National Vocational Qualification (NVQ) system. NVQ which certifies an individual’s skills, is a nationally recognised certificate that confirms that an individual possess skills up to the respective NVQ level in that occupation. (The NVQ framework entails seven levels of qualifications)

The initiative also sought to provide national and international recognition to qualifications issued by numerous technical and vocational education institutions in the country.

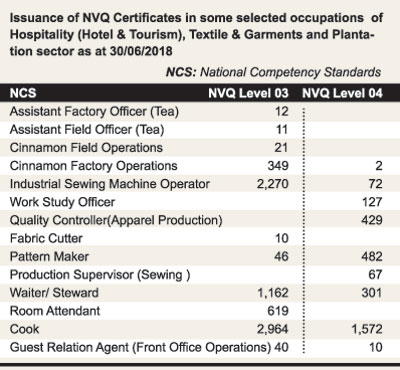

Despite the NVQ scheme being in operation for more than a decade, its application by the private sector for the purposes of skills certification, skills development, recruitment of candidates and employee promotions has been sluggish. To mitigate this gap, the Employers’ Federation of Ceylon (EFC), in a progressive move, has launched an awareness programme together with TVEC which is piloted in plantation, apparel and hotel sectors, the Sunday Times learns.

While creating awareness about the NVQ scheme among a wider group of personnel with hands-on-experience in these sectors, which entitles them to a career path, the project also intends to certify a critical mass of employees in these sectors as nationally recognised skilled craftsmen, points out the Director General of the EFC, Kanishka Weerasinghe. “During our preliminary discussions with these personnel, it was obvious that their knowledge about NVQ standards was very low. The situation among the SMEs (small and medium enterprises) which accounts for more than 95% of the manufacturing units in the country is unlikely to be better,” remarks Mr. Weerasinghe who attributes this ‘slow progress’ largely to the absence of an aggressive social marketing programme to reach out to a wider audience in different industries and sectors.

Kanishka Weerasinghe

Being the nucleus of the employers, the EFC’s reach to a vast segment of the labour market has given it the distinct advantage of mobilising employers to give their workforce recognition for the skills, notes the EFC Chief. The programme has already trialled several sessions and, depending on the success of the pilot project, it is to be extended to other enterprises representing the manufacturing and service sectors within the EFC membership, he says.

Promoting NVQ among those with hands-on-experience will not only offer recognition to their inherent skills but also boost the image of an organisation which employs a skilled work force, says S.U.K. Rubasinghe, Director- NVQ of the Tertiary and Vocational Education Commission (TVEC).

The EFC-TVEC collaboration is also a manifestation of the country’s skilled workforce in which we should take pride and at the same time deserves recognition. “We need to take pride in our skilled workforce which sadly lacks awareness of the career growth NVQ enables,” observes Mr. Rubasinghe who illustrates the career path it promotes from the certificate and diploma to the degree level. Many operational level workers in the private sector are often ‘stuck in the rut’ with poor awareness says Mr. Rubasinghe who applauds the EFC for taking the initiative to promote it in the private sector. “The move also encourages competition between the state and the private sector as NVQ is an entry qualification for technical jobs in the state sector.”

The qualification, as the Director-NVQ, further points out is an internationally recognised one entailing theoretical knowledge as well. “Despite being skilled, a large majority of our workforce is ill-equipped with the industrial jargon, which becomes a bottle neck in terms of promotions and overseas job interviews.” The skills awareness programme also aspires to issue a ‘Skills Passport’ which will recognise other soft skills of the certificate holder. This is going beyond the present NVQ certificate which is confined to the level of technical competency of the certificate holder. The proposed Skills Passport, as Mr. Rubasinghe explains, will contain language competency, communication skills and other skills such as leadership qualities which will enhance the employability of a NVQ Certificate holder both locally and internationally.

S.U.K. Rubasinghe

Speaking to the Sunday Times, Senior Manager, General Management and Operations, Polytex Garments Ltd, Indika Gamage says that the initiative helps the apparel industry to position the Manufacturing Team Members (MTMs) at a higher level, adding more value to the product. “The landscape of the apparel industry is fast changing and attracting millennials to the industry, especially at Machine Operator level which is one of the most daunting tasks, for which repositioning of the work force is a must.” He further notes that an exercise of this nature helps the industry to reduce the ‘layers of the Management’ and thereby equip the MTMs with the multiskilling which the manufacturing process requires.

The entry of the MTMs into the manufacturing process will call for more techno advanced machinery coupled with enhanced implementation of built-in-quality concepts. Mr. Gamage further surmises: “the better educated workforce will be able to flatten the current organisation charts or hierarchy which prevails, and restructure the apparel industry. Moreover with experience and education in technical and technological advancement, they will be able to pursue management or technical career paths of their choice.”

Extending the skills recognition programme to the plantation sector is a case of “nobody’s child” becoming “somebody’s child,” avers the former Chairman, Tea Planters’ Association of Sri Lanka and the Managing Director of Kelani Valley, Talawakelle and Horana Plantations, Roshan Rajadurai.

“Despite the contribution to the national economy for 150 years, the work force on tea plantations had not received adequate technical training and the recognition that accompanies it,” maintains Mr. Rajadurai who welcomes the initiative as a timely move, given the modern day demands of the industry. The benefits are multi-pronged says the senior professional. “While offering dignity of labour as skilled people, the programme is also the first streamlined approach towards skills development in the sector. It is also a refreshing exercise for the industry which is navigating turbulent waters.”

In a setting where our tea is acclaimed as the ‘most certified tea’ in the world, a skilled workforce becomes imperative for global branding, points out Mr. Rajadurai who applauds the programme for encouraging the tea industry to become a ‘people-centric’ venture, moving away from the ‘product-centric’ nature it had traditionally been. The programme which is being trialled in 60 estates, also targets the training of kanganis. The response to the on-site programme has been quite encouraging, Mr. Rajadurai says, adding that this opens a career path for the plantation workforce defying the traditional image associated with the sector.

The project which will be implemented in two phases will engage multiple stakeholders including NAITA and other vocational and training experts. Training of selected employees as Assessors is among the highlights of the programme. As the EFC’s Director General further noted the underlying objectives of this long-term initiative are many, including the creation of a value system to enhance the integrity of labour, retention of employees as well as mobility of skills both within and outside of the country. “Besides, if we are to transform our country as a destination for FDI, it would be imperative for us to hone the skills of our workforce. We cannot afford to leave any of them behind.”