News

Home-grown ‘waste-to-treat-waste’ project

The ‘seed’ took root at a chance networking meeting with two people leisurely sipping drinks at the rear of the hall, was ‘nurtured’ in a simple physics laboratory and finally ‘blossomed’ into a major innovation in the smelly junkyards of two big-time industries.

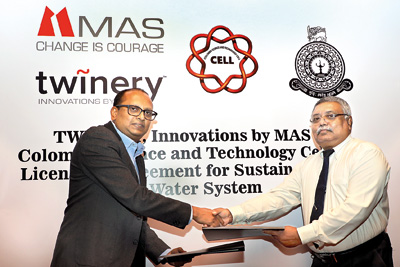

A red-letter day: A handshake between MAS Holdings Chief Innovation Officer Ranil Vitarana (on the left) and Colombo Science & Technology Cell Chairman Prof. K.R.R. Mahanama after the signing of the Licensing Agreement

It was on Tuesday during a brief one-hour ceremony that the unique ‘fruit’ was officially introduced – a home-grown and sustainable ‘waste-to-treat-waste’ solution, which is a dire need for Sri Lanka, beleaguered under the accumulation of much waste.

This innovative technology has blossomed forth from a minimally-funded (just Rs. 16,000) undergraduate research and has far reaching environmental, industrial and economic benefits for both the textile and aluminium industries, the Sunday Times learns.

‘TWINERY’ – the innovation arm of MAS Holdings and the Colombo Science and Technology Cell signed the Licensing Agreement for this novel Sustainable Waste Water System at the College House, University of Colombo on Tuesday.

While MAS Holdings is a big player in the apparel industry, the research concept of ‘waste-to treat-waste’ has been developed by the Department of Physics of the Colombo University working with the blessings of the Colombo Science and Technology Cell, the business-arm of the Faculty of Science established to strengthen university-industry collaborative research.

Vice Chancellor Prof. Chandrika Wijeyaratne reiterated the importance of university-business linkages which benefit the undergraduates, researchers and industries.

“The University of Colombo has a long history of collaborating with successive governments, local industry and the corporate sector in the three major areas of service, training and research,” she said, adding that Tuesday was a red-letter day, marking a highly ranked outcome of a decade long initiative to develop a collaborative relationship between the university and the industry.

Before delving into the technology which uses waste from one large industry – aluminium – to treat waste from another industry – apparel or textiles – the Principal Researcher and Senior Lecturer in Physics, Dr. Dilushan Jayasundara said that through his work he strives to safeguard the environment. This is his second invention, the first being the patented (USA) process of converting Sri Lankan graphite to Graphene.

Focusing on this innovation of ‘waste-to-treat-waste’ which is patent-pending, he explained how his team has moved away from the “traditional” concept of waste management which is the 3Rs of ‘Reduce, Reuse and Recycle’.

Prof. Chandrika Wijeyaratne

Dr. Dilushan Jayasundara

Smilingly Dr. Jayasundara says how the initial proof of concept was developed at the Physics Department, where this type of research is not within its traditional scope and the seed discussion for the collaboration between him and MAS Holdings Chief Innovation Officer Ranil Vitarana took place at a networking event rather than a formal scientific meeting.

“The researchers did not always have the luxury of a pleasant laboratory setting but worked in the backyard of both the aluminium and apparel industries under tough conditions,” he pointed out.

Dr. Jayasundara attributed the success of the efforts to “teamwork, passion and commitment” of all those involved – the researchers and coordinators from the Colombo Science and Technology Cell and MAS Innovations.

“This technology will bring significant environmental and economic benefits to both industries,” he added.

MAS Holdings Chief Innovation Officer Ranil Vitarana said that over the years, MAS as the largest apparel industry in the country has been looking for ways to bring industry and academia to work together. But there has been trepidation and suspicion about people stealing others’ ideas and barriers including legislation and other things.

He was amazed when he saw experiments at the Department of Physics, University of Colombo where Dr. Jayasundara showed him how some materials were put into dyed water and the water came out clean from the other end.

“Invention is when you take cash and make ideas. Innovation is to take that idea and convert it back into cash. This is what is being done with this project,” said Mr. Vitarana.

Pointing out that MAS uses high-end technology to make sure that the waste water is treated to the highest level, he added that this waste management process will save large amounts of foreign exchange that they currently spend on chemicals to purify waste water.

| What is this technology? | |

| “Solid waste from the aluminium anodizing industry is collected and converted with minimal processing to remove colour from dye-containing waste-water in the apparel and related industries,” explained Dr. Dilushan Jayasundara of this technology developed within eight months. He pointed out that the dissolving stage of the modified aluminium sludge generates aluminum hydroxide which is used as an adsorption-coagulant in removing colour from the waste-water. It is revolutionary filter technology used in a sustainable closed-loop model, it is learnt. When the sludge settles it is used in the manufacture of eco-bricks, with waste quality analysis ensuring that the entire process is safe and managed within local and international norms of environmental safety, he added. The research team headed by Dr. Jayasundara included Consultant/Co-investigator and Senior Lecturer in Chemistry, Dr. Shashiprabha Vithanarachchi; Shalika Meedin from the Colombo Science and Technology Cell; undergraduates Kushani Hettiarachchi & Kasun Sankalpa; and Harsha Deraniyagala from the MAS Fabric Park . The coordinating team included Prof. Thusitha Abeythunga, Dr. M.N. Kaumal, Shuraiya Amath and Yasiru Kumarasiri from the Science and Technology Cell and from MAS Innovation Pvt. Ltd. Ranil Vitarana and Sarah Dole. |

| What is the impact? | |

| Sri Lanka’s textile industry uses imported costly agents to treat waste-water, says Dr. Dilushan Jayasundara, pointing out that through their experiments they found that these agents and Al-sludge worked in a similar manner with regard to their ‘coagulation’ effect (in a solution when particles separate and settle at the bottom of a container forming a gel/sludge). The waste-water from the textile industry when mixed with these agents or Al-sludge came out without its colouring (dyes). The dye was being absorbed by the Al-sludge, working like the agents. “Therefore, this new finding has proved the possibility of partially or even fully replacing the costly imports with Al-sludge, of course, based on its availability,” says Dr. Jayasundara, pointing out that this new technology could be used within the existing waste treatment infrastructure in the apparel industry globally as well. “It also has the potential to eliminate solid waste from the aluminum industry that would otherwise have to be disposed in a different manner. With this innovation, the potential for total industrial sludge-waste of the aluminium industry and MAS is expected to be reduced by around 40-50%. When up-scaled, there is the possibility of totally eliminating all aluminium sludge-waste that would otherwise have gone into incineration or expensive end-processing,” added Dr. Jayasundara. |