Making lime a fruit for all seasons

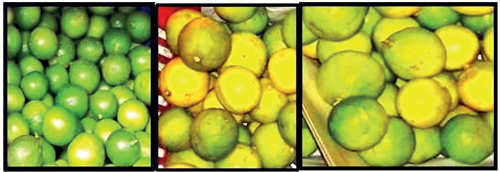

Limes as harvested (left); after 60 days (centre); and after 60 days with pre-storage treatment (right). Note change from green (left) to yellow (centre); but reduced yellowness from centre to right

In Sri Lanka, fresh limes (Citrus aurantfolia) have a year-round demand as they are used for a variety of purposes such as domestic cooking, food processing, indigenous medicine, cosmetics and health care products. The majority of the fruit is consumed fresh, both nationally and internationally. In 2019, the area under lime cultivation in Sri Lanka was 10,238 ha; and the total production was 16727 tonnes. The quantity of lime and lemon exported is 600 tonnes, earning foreign exchange of USD 647,000

for Sri Lanka.

Lime is a seasonal fruit. Peak production falls between mid-April to mid-July in the dry zone areas. During this time the price drops to as low as 0.4 USD/kg, causing lime growers to leave the fruit unharvested, because the price is not sufficient to recover the cost of production. However the price of lime rises to as much as 3.75-6.25 USD/kg during the off-season, making it unaffordable to consumers. Lime is identified as one of the high priority crops by the National Committee of

Post-harvest Technology and

Value Addition.

Two strategies, one aim

While the lime industry is growing significantly, making the product available throughout the year during both peak and off seasons continues to be a challenge. On the one hand, the market surplus of lime should be overcome; on the other hand, a year-round marketing strategy should be ensured. To achieve this, limes that are picked in peak season but not immediately required, need to have their life extended so that they can be used during off-season.

Lime, like most fruits, is a perishable commodity. Research was carried out by the National Institute of Postharvest Management (NIPHM) towards this end, with funding from the National Research Council of Sri Lanka. Dr Harindra C. Wickremaarachchi of the Research and Development Centre at the NIPHM was the lead investigator.

The study evaluated the effect of pre-storage treatment by salicylic acid and putrescine on fruit quality and post-harvest life of lime (C. aurantifolia) during cold storage. Limes were harvested at the optimum maturity stage and quickly transported in plastic crates carrying 18-20 kg of the produce. Fruits were divided into seven groups, each containing 100 fruits. One group was the control and the other two sets, containing three groups each, were dipped for 15 minutes in aqueous solutions of salicylic acid and putrescine having differing concentrations. The salicylic acid concentrations were 138, 276 and 414 mg/L; the putrescine concentrations were 81, 161 and 242 mg/L. Fruits were then air-dried and stored in cold rooms (10-13 deg.C, 90-95% relative humidity) in plastic crates. Various measurements were taken before the treatment and at 14, 28, 42 and 56 days after the pre-storage treatment.

A range of parameters were investigated for the peel, the entire fruit and the juice from the fruit. Peel colour was measured using a colour difference meter. The preservation of the original greenness and delaying the onset of yellowness is desirable as is the preservation of the original lightness in colour. Peel chlorophyll content was measured using a spectrophotometric method, and here too the objective is to maintain the original high chlorophyll content. The parameters investigated for the entire fruit were physiological loss in weight, total soluble solids and titratable acidity.

The pH value was the parameter of concern for juice quality. The physiological loss in weight, the peel lightness and yellowness, and the total soluble solids increased with storage time while the peel chlorophyll content, the titratable acidity and the peel greenness decreased. Juice pH showed a slight increase with the storage time. All of these changes were reduced compared to the control due to the pre-storage treatments.

Increase in the post-harvest

life of lime

The results indicate that the post-harvest life of lime can be extended by two months so that it can supply the market even during off season, thus adding value to the industry while avoiding losses caused by either scarcity or overproduction. Post-harvest dip treatments of 276 mg/L of salicylic acid or 81 mg/L of putrescine were similarly effective. However, it is recommended that salicylic acid treatment be used, because putrescine is more expensive than salicylic acid.

The identified technology can be transferred to lime growers, wholesalers, processors and those interested in the storage of fresh lime, aiming to market them off-season. Transfer of the technique to lime growers may lead to the development of lime-based agribusiness, leading to employment opportunities. The project also contributed to human resource development.

As part of this project, a cold storage facility and an EC meter at the NIPHM were installed and they are used for other projects as well. During training programmes and workshops, the cold storage facility is used to demonstrate the importance of low-temperature storage of fresh fruits and vegetables to extend their post-harvest life. Although outreach activities were not carried out with this research, the price fluctuation from the peak season (Rs 50 to 70) to the off-season (Rs 600 to 1000) will enable a lime farmer to invest in the postharvest treatments of lime along with cold storage, so as to increase profits.

The study is mainly aligned to the Sustainable Development Goals (SDGs) No. 12 (Responsible production and consumption) and No. 4 (Quality education). It also addressed other SDGs, such as No. 1 (No poverty), No. 2 (Zero hunger), No. 3 (Health and wellbeing) and No. 9 (Industry, innovation and infrastructure).

This research was funded by the National Research Council under grant IDG 15-157, and awarded to Dr Harindra C. Wickremaarachchi of the National Institute of Postharvest Management. Asitha Jayawardena was commissioned to write this article as part of the science publicity programme of the National Academy of Sciences of Sri Lanka.