Rileys'

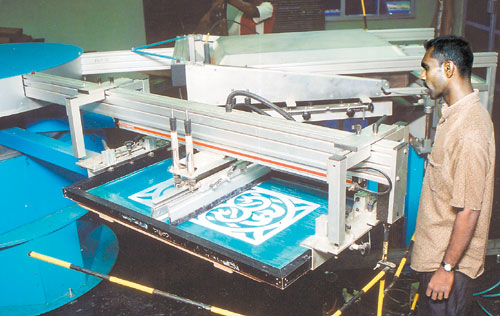

success spawns global copycats The company, which has representative firms in the U.K, Holland, Japan and Australia, is also expanding its operations in to South America and the territories of the former Soviet Union. With over 500 patented products under its umbrella, Rileys exports value added coir as well as rubber floor covering products to 28 countries. It has an annual turnover of Rs 600 million. Major retail chains such as Homebase, Wallmart, Kmart, Lowes, Jusco and Home Center are some of the main importers of Rileys products worldwide. "Even with a simple product like coir fibre, because of our creativity and high value addition we have created a niche market of our own," Crishan Mendis, the company's chairman, told The Sunday Times FT in an interview. "Our products have gone down really well with consumers in international markets. Because of our success others have realised that this is the way to go and are trying to get into the same markets by copying us." Rileys has successfully litigated against a number of companies in countries like Japan, India, Taiwan, Germany, U.S, U.K and France for the violation of its patent rights. These include top super market and DIY (Do-It-Yourself) chains in Europe, resulting in a substantial amount of stock being destroyed and compensation being awarded to Rileys. The worst competition comes from India, a big coconut producer, and cheap imitations from China have emerged as a new threat to Rileys' patented coir products such as boot scraper mats in the world market. Boot scraper mats of cheaper and inferior quality have made a significant erosion in the market share of Rileys, Mendis said. The coir boot scraper mat is a Rileys innovation and is considered a flagship product of the company. Although the company owns patent rights for this product as well as a considerable range of other mats, manufacturers from countries like India and China are constantly making patent infringements. Mendis noted that so far, defending the patents of the products of Rileys in China has been most difficult as the laws as well as the legal system of the country require compelling evidence to make a case against such manufacturers. The company provides employment for 110 people at its Ja-Ela factory and another 20 at its Dankotuwa factory which manufactures rubber mats and recycled rubber mats. It also has almost 1,500 external employees as sub contractors. The coir industry here suffered a set back recently due to the scarcity of coir fibre because of unhealthy weather conditions. But Rileys was able to make profits last year because its higher value added end-products allow it to command high prices and maintain good profit margins to sustain the firm in difficult times. "Consumers are willing to pay a premium price because of the creativity and the innovativeness of our products," Mendis said. However, the increase in the price of rubber in the market had an adverse effect on prices and in turn on profits. The company out-sources many of its operations to small industries in all parts of the island. Rileys provides the technical knowledge, raw material and at times machinery to the external workers. Supervisors and quality control staff visit these factories on a regular basis in order to ensure quality."This is also a contributing factor for our low levels of cost and the high profit margin," said Mendis. Mendis also said that the industry is facing labour shortages due to health hazards and difficult working conditions. Although the company started out in 1989 like most other companies by manufacturing and exporting traditional coir based products, Rileys decided to diversify into value added coir products specifically in the floor-covering sector. This step proved to be the winning formula for the company. Today Rileys is recognized the world over as an innovative and top-of-the-range producer of floor coverings. "The hallmark of our success has been our creative products," Mendis said. The musical mat and the water spray boot wiper are two new innovative products, which were made available this year. There are no qualified designers at Rileys and innovation stems from all levels of employees in the company."We practice an open door policy and anyone can display their creativity without any prejudices," Mendis said. Employees are also recognized for their abilities and in some cases are sent abroad for training or to visit related exhibitions in order to gain a broader perspective of the industry. Most of the raw material for production is acquired locally with the exception of wire for certain types of mats which are imported in order to assure the quality of the product. "Consumers are willing to pay a premium price because of the creativity and the innovativeness of our products," Mendis said. However, the increase in the price of rubber in the market had an adverse effect on prices and in turn on profits. The company out-sources many of its operations to small industries in all parts of the island. Rileys provides the technical knowledge, raw material and at times machinery to the external workers. Supervisors and quality control staff visit these factories on a regular basis in order to ensure quality."This is also a contributing factor for our low levels of cost and the high profit margin," said Mendis. Mendis also said that the industry is facing labour shortages due to health hazards and difficult working conditions. Although the company started out in 1989 like most other companies by manufacturing and exporting traditional coir based products, Rileys decided to diversify into value added coir products specifically in the floor-covering sector. This step proved to be the winning formula for the company. Today Rileys is recognized the world over as an innovative and top-of-the-range producer of floor coverings. "The hallmark of our success has been our creative products," Mendis said. The musical mat and the water spray boot wiper are two new innovative products, which were made available this year. There are no qualified designers at Rileys and innovation stems from all levels of employees in the company."We practice an open door policy and anyone can display their creativity without any prejudices," Mendis said. Employees are also recognized for their abilities and in some cases are sent abroad for training or to visit related exhibitions in order to gain a broader perspective of the industry. Most of the raw material for production is acquired locally with the exception of wire for certain types of mats which are imported in order to assure the quality of the product. st of the raw material for production is acquired locally with the exception of wire for certain types of mats which are imported in order to assure the quality of the product. |

||||

Copyright © 2001 Wijeya Newspapers

Ltd. All rights reserved. |